in a testament to my powers of procrastination, for – oh – about five years since we moved in, i’ve been thinking about putting shelves in a closet in our 100 year old house that was, curiously, lacking any. it’s a big space, about 9 feet long and 2 feet deep, and installing shelves could cure The Clutter Problem that continues to plague us. such a simple project! why had it taken me so long to just drill some holes and hang the shelves?

it never once occurred to me to ask why prior home owners had never installed shelves.

the answer quickly revealed itself when i tried to drill holes in the cedar to install screw anchors. after boring quickly through the wood, the bit immediately stopped against something very, very solid. i thought maybe the drill bit was dull so i went to our local hardware store and purchased a shiny, new titanium bit that advertised itself as being good for all materials except metal.

nothing. no amount of pushing, pounding or tapping could get the drill to make the slightest bit of progress. so, using Impeccable Powers of Logic, i went back to the hardware store i went to buy a special masonry bit on the assumption that if the titanium bit wasn’t working that i must be working against some sort of concrete or brick. our house has a stucco exterior and plaster interior walls so brick or concrete under the cedar would be a bit of a mystery, but sometimes 100 year old houses like to keep secrets.

since i learned long ago that there’s nothing that can’t be helped with an extra helping of elbow grease, i really leaned into the masonry bit with great gusto while drilling at high speed. but despite all my huffing and sweating and cursing i managed to produce nothing more than curious wisps of smoke around the cedar hole.

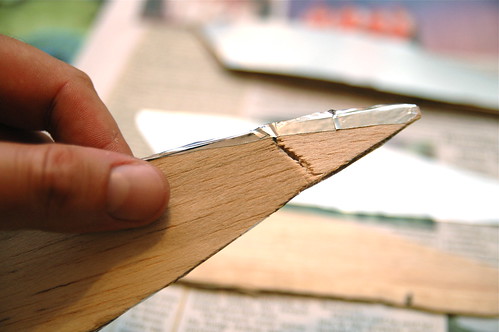

and eventually i managed to simultaneously break the 5/16″ masonry bit shaft and bend the end of the bit. not that’s talent. i took it back to the fine folks at nelson’s agri-center and they were so impressed they gave me a free replacement, though it was a headscratcher for the Nice Man behind the service counter. “you sure you ain’t trying to drill through metal? i’ve never seen a burnt and bent masonry bit. maybe try starting small and work your way up to 5/16ths.”

so armed with a variety of masonry bits i went home and started small with an 1/8th inch bit. which promptly snapped after i applied too much pressure and let it get too hot.

eventually after a few more trips to the hardware store i finally discovered the secret to penetrating the impervious mystery material – go slow, don’t apply too much pressure, don’t the bit get too hot and work slowly up through 4 bit sizes from 1/8th to 5/16th. patience is the key.

success! finally! nearly 50 square feet of shelving where there had been none. now i just need to come up with some sort of organizational system for the shelves. and a door for the 92 inch opening. ah, the joys of never ending projects.

the mystery still remains, though, as to the true nature of The Mysteriously Impervious Material. the cedar closet is in room that was an addition to house at some point after the original construction and it’s built on what would have been an exterior wall. all interior walls are plaster, but on a previous project when i was installing a new light in our bathroom, i discovered a hole under vanity on the exterior-facing interior wall. i was surprised to find over-sized bricks, right under the plaster and lathe.

i assume all the exterior walls are brick? perhaps the owners just put cedar over the brick in the closet and didn’t even bother putting up plaster? was our house originally brick and stuccoed over later? or is this some sort of special Magically Impervious Stucco Brick?