the alternator melted down so it’s time to pretend i’m a gearhead and get all greasy and fix it! one of the nice things about having a galaxie 500 with a 289 motor is it’s very easy to find parts since all the ford windsor V8s have basically interchangeable parts and were in production for many years.

sure enough the local parts store had an motorcraft stamped alternator a the motor for a princely sum of about $32. $45 for the lifetime warranty which means i’ll never have to buy another alternator again.

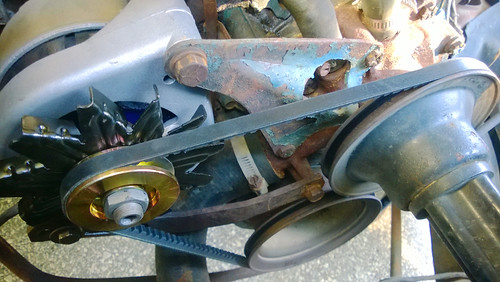

but first i had to get the burned out alternator out. i can never remember which wire goes where so before unhooking it completely i figured it was smart to take a picture of the old alternator.

there are just two bolts holding the alternator in place. who knows when the last time was the bolts were loosened. it’s been my experience that the trick to replacing parts in an old car often involves figuring out how to remove rusted bolts without snapping off the heads. thankfully, the main bolt came loose relatively easily. however, the bolt attached to the pivot arm ( which allows you to adjust the alternator to tighten the drive belt ) did not want to budge. luckily i was able to take out the alternator with the pivot arm attached. of course, i first tried the ol’ squirt some wd-40 on the bolt and bang on it with a hammer which didn’t do much to loosen it. so i attached some copper pipe to the rachet to create more force with lever and held it in place by stepping on the lever arm and vice grips attached to the alternator housing and sloooooowly cranked on the bolt.

i was guessing i had about 50% chance of snapping the bolt head but i figured it wasn’t the end of the world since the rest of the bolt would be in the old alternator and the worst that could happen is that i would spend some time finding a replacement bolt. but as it happened, my plan worked flawlessly and i eventually worked the bolt loose without snapping it!

with the new alternator in place, now what do i do use to rotate it on the pivot arm to create the right amount of tension on the drive bent so it’ll turn the fan and water pump without slipping? you need something that’s long enough to create enough force and skinny enough to fit between the narrow space between the alternaor and the engine block.

the two foot drill bit i used to drill a hole through the trees for the treehouse deck gave me just the right amount of leverage. perfect!

and whoila – with a little ingenuity, $45 ( well, i guess maybe it was closer to $60 when you include the cost of the new drive belt ) and few hours, the galaxie is back up and running!

you get the post title is a reference to “zen and the art of motorcycle maintenance”, right? of course you do.