warmer days and cool nights mean one thing around these parts – it’s maple syrup makin’ time! freezing nights and warm days induce sap flows as the trees move stored sugar in their roots up the trunk to get ready for spring leaves.

we had a chance to visit some of the fine folks that produce for maple valley cooperative and watched as the sugary sap from about 1,800 trees flowed through lines into a 1,000 gallon holding tank before being pumped to the “sugar shack” to be evaporated down to maple syrup.

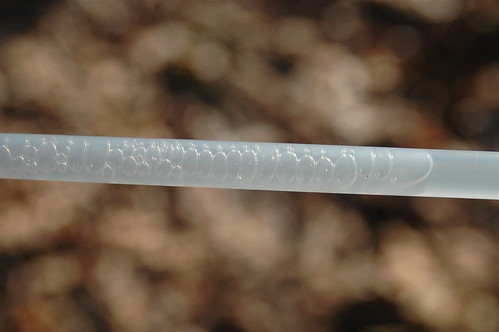

maple syrup was once harvested by tapping a maple tree through the bark and letting the sap run into a bucket, which required daily collecting and a whole lot of labor when you’re collecting from thousands of trees. these days, the taps flow into plastic pipelines that usually use the force of gravity to send the sap into holding tanks.

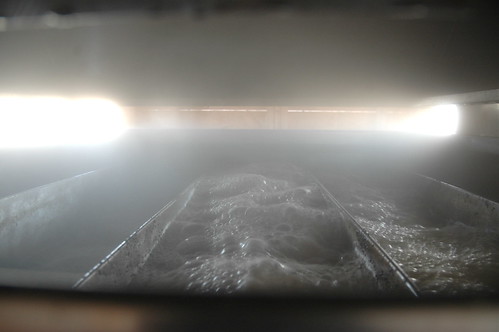

after the sap is pumped to the sugar house it’s boiled down to maple syrup in an evaporation pan. it takes about 40 litres (10 gal) of sap to be boiled down to 1 litre (1 quart) of syrup! and a mature sugar maple produces about 10 gallons of sap or 1 quart of syrup during a single season. as is common these days, the maple valley producers we visited use reverse osmosis to remove 75 to 80% of the water from the sap prior to boiling, reducing energy consumption during the production process.

odin had a great time learning about how the yummy maple syrup he enjoys through the year gets made!